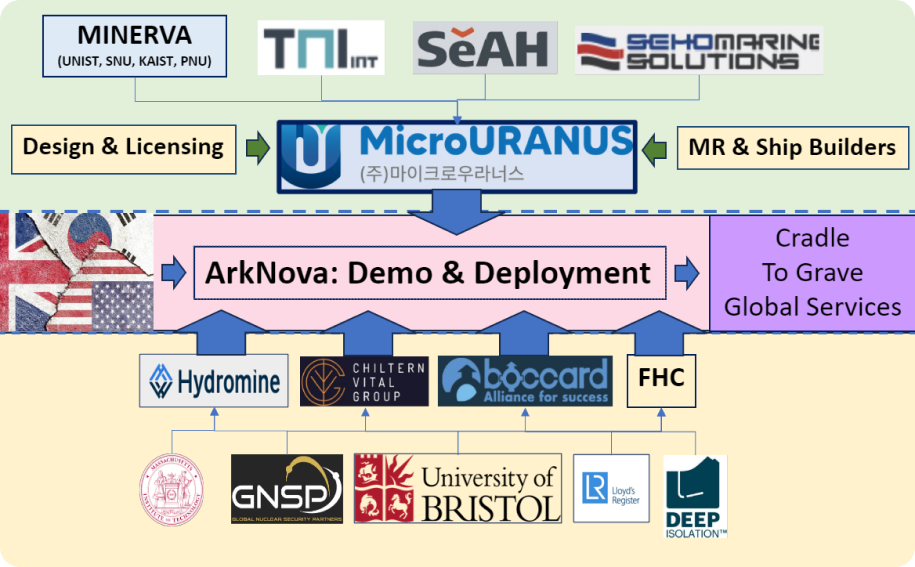

Strengthening Global Competitiveness Through Partnership

We are achieving innovation through collaboration with trusted partners. By building partnerships with companies that possess expertise in their respective fields, we maximize efficiency and work towards our shared goals of sustainable growth and success. We maintain close relationships with our partners as we shape the future together.

SMR 'Flexible Operation' Integrated with Renewable Energy → Distributed Power Law Application and Export Competitiveness

Challenges of increased damage from fatigue, stress corrosion, and wear due to rapid fluctuations in temperature, pressure, and flow during flexible operation

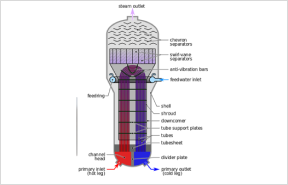

For LWR, MSR, SFR, and LFR, prevention of steam generator heat exchanger tube leaks is essential

- Piping suitable for different environments must be composed of double-walled pipesElimination of high-temperature corrosion and hydrogen explosion risk for PWR nuclear fuel Zr cladding

- Accelerating licensing and export by meeting the requirements of the European and Korean Green TaxonomyEarly Commercialization of Breakthrough Technologies and Capabilities for Profit Generation

With expertise in both dual-pipe material technology and component design, we hold a significant competitive advantage in development and commercialization

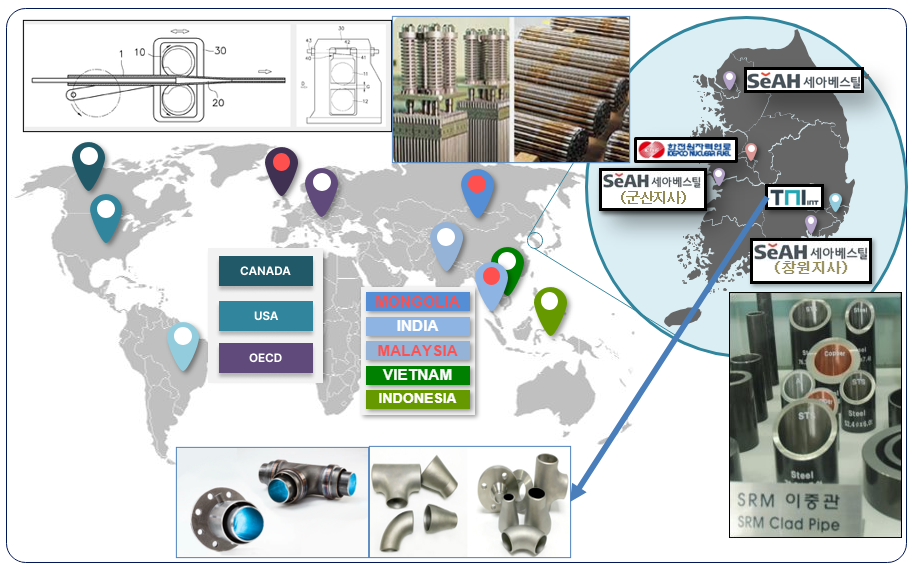

- We possess capabilities in dual heat exchanger tube and steam generator design, as well as extensive experience in manufacturing bi-metal pipesWe have established a global collaboration framework with world-leading companies to produce and market dual pipes for non-nuclear applications

- Partnering with top tube manufacturers such as Korea Superconductor Co., Ltd., SeAH Besteel Corp., KEPCO Nuclear Fuel Co., Ltd., and TNI Co., LtdBy commercializing and accelerating the sale of innovative materials for MicroURANUS through our partnerships, we generate significant revenue.

Hydrogen Explosion of Nuclear Fuel Rod on LWR

Nuclear Fuel Corrosion in Lead-Cooled Marine Reactors

Bi-metal tubes

SG Tube Leaks

Ti/SS → Steam Erosion of Sea Water Heat Exchanger Tube – Ti/SS

ArkNova Power Consortium (proposal)